Patterns, Casting Molds and Injection Molds

Tool Shop Capabilities:

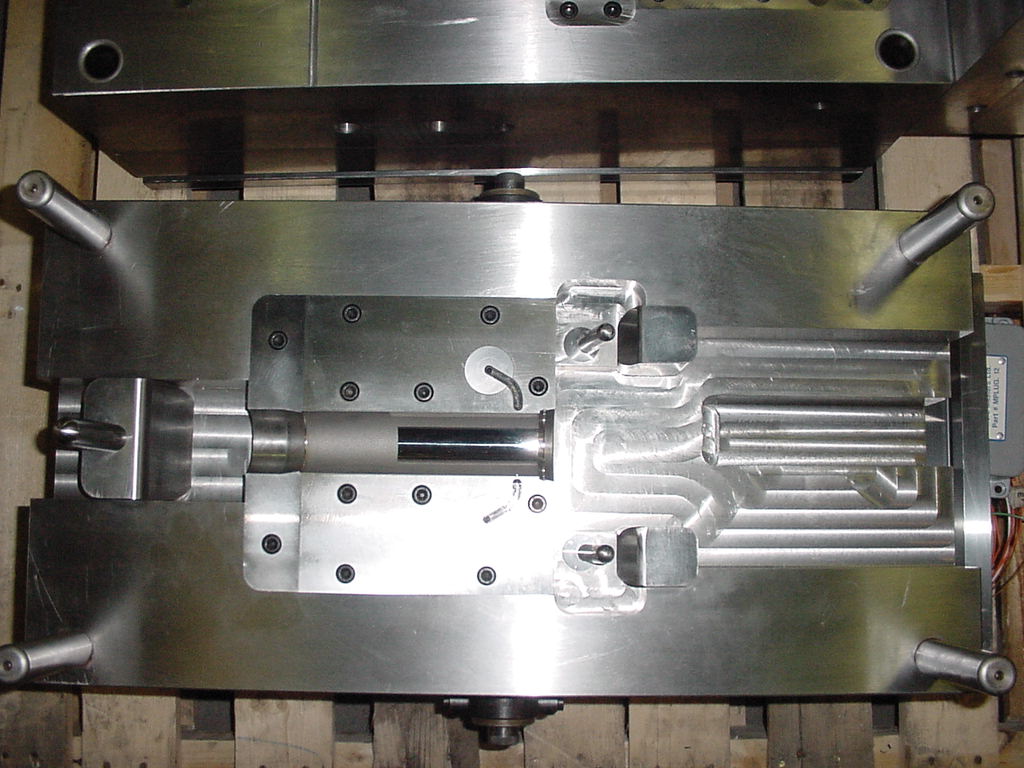

The Steinmetz Tool Shop utilizes the latest technologies in the industry and employs a diversely talented staff with years of experience to build, repair, as well as perform maintenance on molds. Our shop includes Haas VF-4 CNC 3 Axis Milling Center with Offline Programming, MasterCam 10 3D Tool Path Generation Software, Bridgeport EZ Trak Haas VF-2 2 Axis Milling center with Offline Programming, EZ Mill Tool Path Generation Software, Manual Milling Machines with Digital Read Out. We also have CNC Lathes, Ram EDM Machines, Wire EDM Machines, Surface Grinders, Centerless Grinding Machines, Honing Machines, Precision Hardinge Lathes, Optical Inspection Stations, Assorted Measuring/Inspection Equipment and Welding Machines.

Mold Building Material and Applications

High and Low Volume Production Injection Molds:

We work with Hardened Tool Steels and Aluminum. We have made injection molds for various applications in the Medical, Railroad, Electrical, Consumer Goods, Military, Industrial, Construction, and Zinc Die Casting industries.

High and Low Volume Prototype and Production Casting Tooling:

Steinmetz can produce Casting molds out of Steel, Aluminum, RTV Silicone and Urethanes, along with SLA (Stereo lithography), Molds and Patterns. Some of the applications for these molds include: Railroad, Mining, Industrial, Machinery Builders, Bridges, and Mixing Equipment purposes.